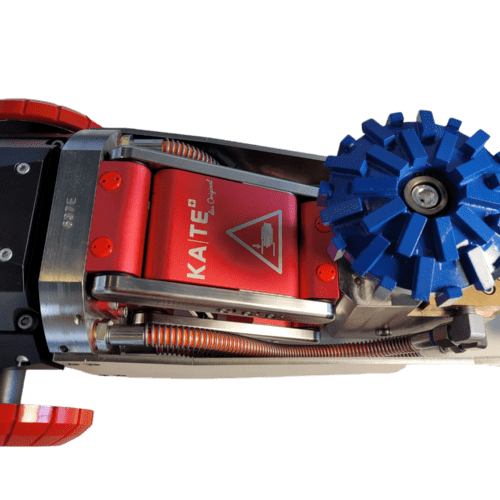

- State-of-the-art 20 kWh battery system with battery management system, safe extinguishing system and exceptionally long service life with up to 9000 charging cycles

- Works without CO2 and noise emissions, complies with stricter laws

- Practically noiseless in battery mode

- Allows work at night

- Hydraulic cutting 4-6h, filling/shuttering 8-16h (depending on other machines operating at the same time such as air conditioning etc.)

- Constant load for generator: higher efficiency, less diesel consumption and less maintenance

- Redundant system: In case of a power source failure (e.g. battery), the system can be switched to a generator.

- Programmable battery: e.g. switch on the climatic refrigerator in the evening to bring resin up to temperature the following day.

- Plug-in system, charging with green electricity from the base

- Charging while working

- Remote maintenance via internet

- Easy replacement of the battery

- Boost mode: up to 35 kW power from battery + diesel generator

- Can be expanded up to 60 kWh battery without generator

- All-in-one solution: everything in one vehicle

- User-friendly with walk-through from command room to rear

- Ergonomic TEG-Keyboard

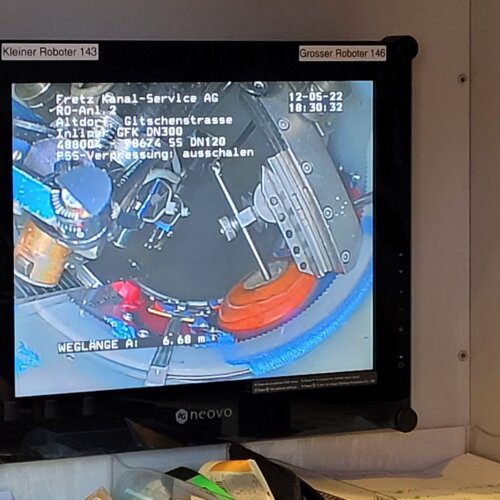

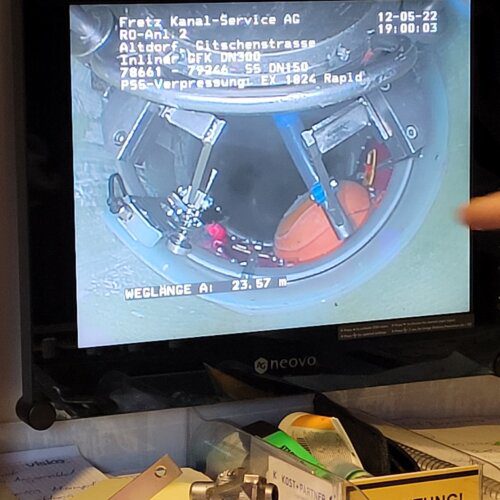

- Control room: instruments at a glance with camera surveillance

- All-round lighting, rain protection flap

- Open design: maintenance accessible everywhere

- Double cable drum: During cutting, prepare resin robot

- Box for any vehicle from 7500 kg upward

- Over 300 liter water tank with heated pump for use in winter

- Maximum comfort for the operator with air conditioning, auxiliary heating, mini fridge and various sockets for kitchen appliances

- Also possible without hybrid system with 17 kVA power generator

- Höchster Komfort in seiner Gewichtsklasse

- Durchgang vom Fahrerhaus bis Heck

- Werkbank für Feldreparaturen

- Alles auf einen Blick im Kommandoraum

- Grosse Heckklappe als Regenschutz mit Beleuchtung

- Reichlich mehr Stauraum als Kastenwagen

- Neue ergonomische TEG-Tastatur

- Rundumbeleuchtung für Nachtarbeit

- Doppelte Kabeltrommel für effizientes Arbeiten

- Mobiles System mit Anhänger: Gute Zugänglichkeit in engen Straßen

- Offener Ausbau: Wartung überall zugänglich, einfacher Austausch von Komponenten

- Über 300 Liter Wassertank möglich, mit beheiztem Wassersystem für Wintereinsatz

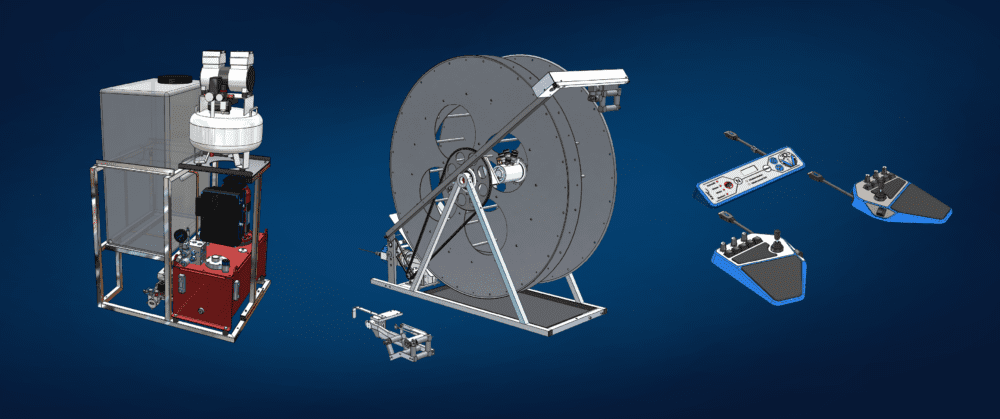

The Compact Basic system is simple and cost-optimised. Compared to the Compact system, the units are individual to provide more flexibility for installation. It contains only what is necessary for the operation of the robots. It was developed for customers who are looking for a cost-effective solution or who want to dismantle a 3500 kg vehicle. The system is ideal for export, where on-site upgrading is ideal. A sewer rehabilitation vehicle can be realized with little investment.

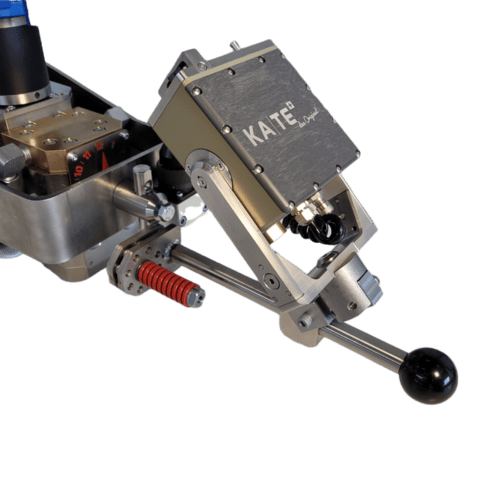

The system consists of:

- Cable drum with separate cable pulling arm

- Hydraulic power unit

- control cabinet

- Control & remote control

- Compressor

- Water tank 210-325 liter

- Water pump

- Optional: slewing crane

The customer can define the installation in the vehicle himself. We will gladly prepare a CAD concept for planning within a few days. Installation with a KA-TE technician is possible. Do not hesitate to contact us.

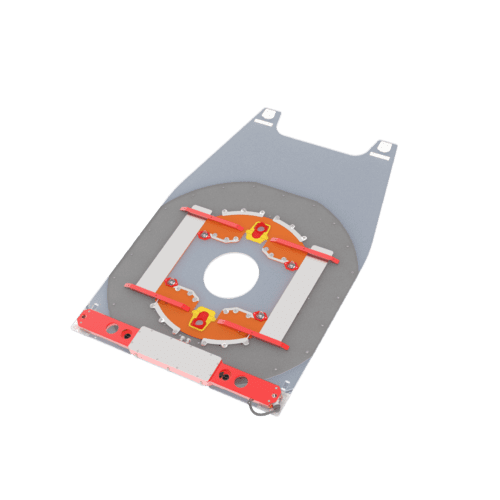

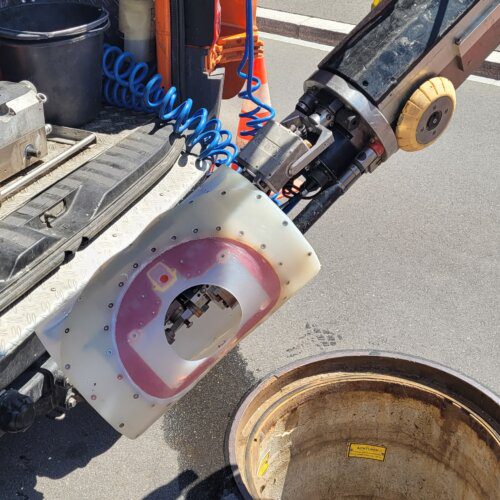

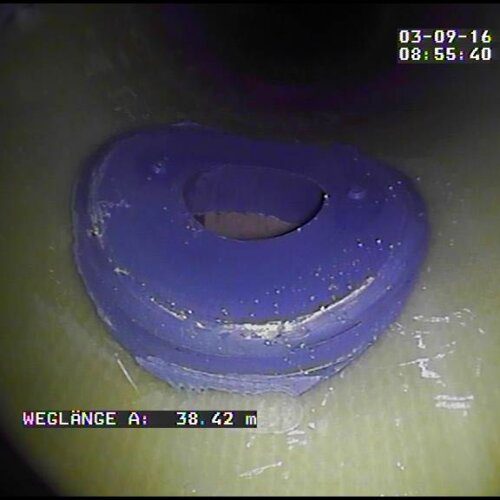

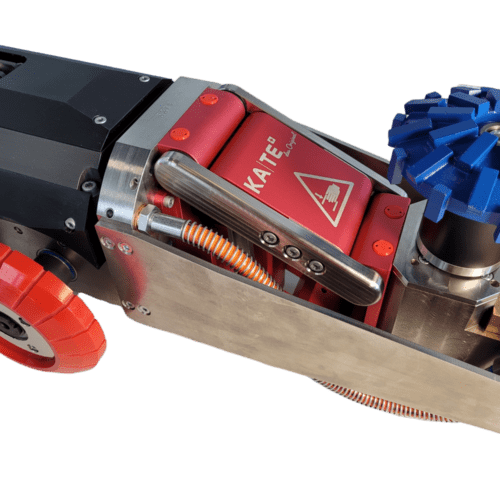

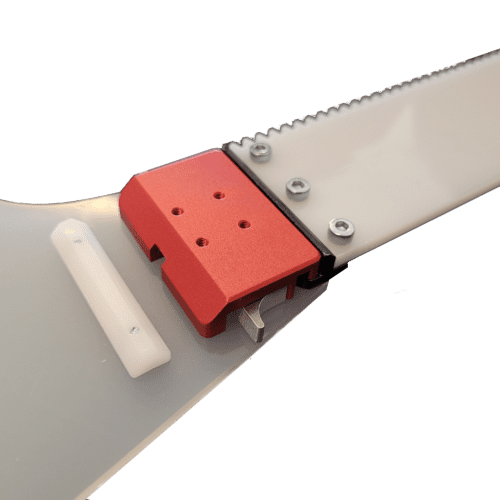

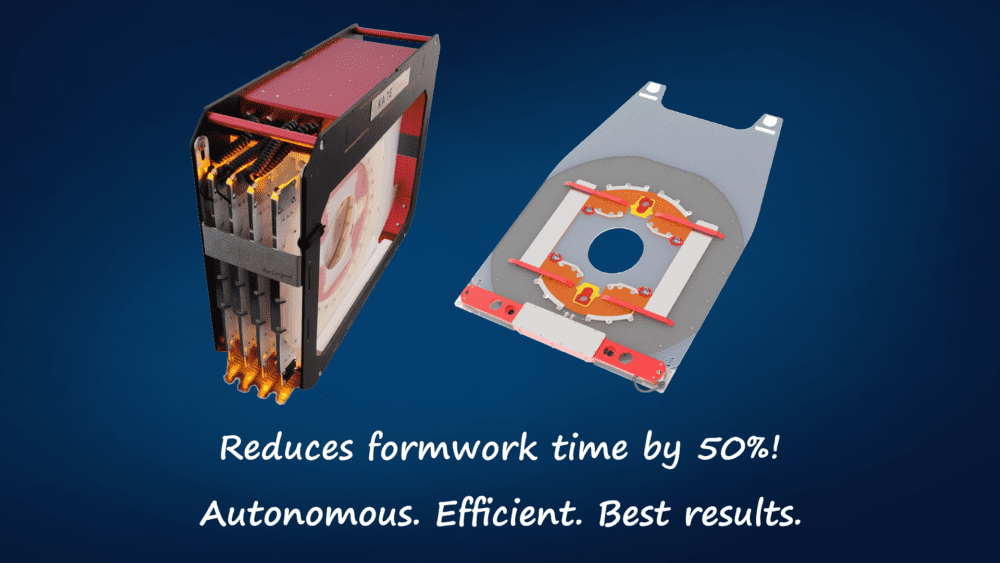

- Enormous time saving for every house connection

- Compatible with KA-TE SM300

- Heating shuttering without cables and robots

- Easy to operate: Heating switched on with magnet, LED lights up

- No time pressure regarding pot life compared to fast resins. Fast resins tend to crack and shrink.

- Rechargeable shuttering with over 1h heating time

- Temperature limited to 90 °C

- Epoxy eyes indicate sufficient resin quantity during grouting

- Sealing ring reduces thin resin runs behind the shuttering

Steineggstrasse 32

8852 Altendorf

Schweiz

Tel: +41 55 415 58 58

info@ka-te.ch

Öffnungszeiten:

Montag – Freitag

07:30 -16:30 Uhr

Gerne demonstrieren wir Ihnen das Können unserer Produkte. Vereinbaren Sie mit uns einen Termin, um sich von uns für unsere Systeme überzeugen zu lassen. Wir freuen uns auf ihren Kontakt.